Welding principle:

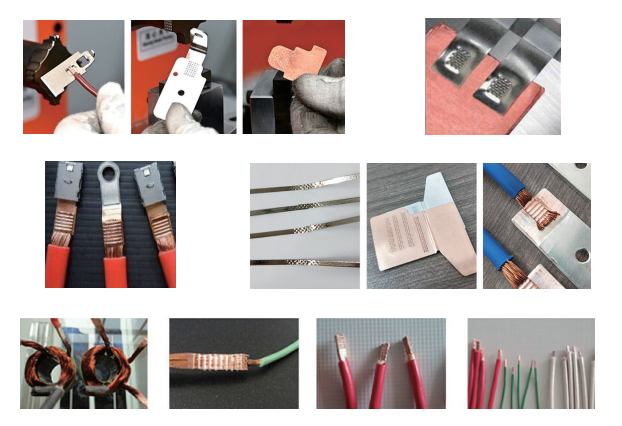

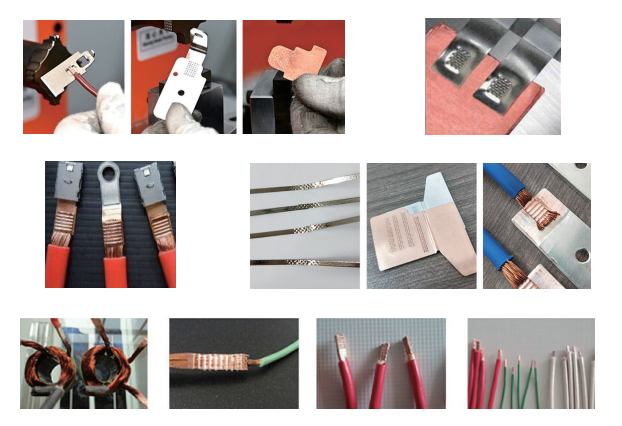

The principle of ultrasonic metal welding is a special method of connecting the same or different metals using the mechanical vibration energy of ultrasonic frequency. During ultrasonic welding, the metal neither delivers current to the workpiece nor applies a high-temperature heat source to the workpiece. Instead, under static pressure, the wire frame vibration energy is transformed into friction work, deformation energy, and limited temperature rise between the workpieces, The metallurgical bonding between joints is a solid-state welding achieved without melting the base material. Therefore, it effectively overcomes the phenomena of splashing and oxidation generated during resistance welding. Ultrasonic metal welding machines can perform single point welding, multi-point welding, and short strip welding on fine wire or thin sheet materials of non-ferrous metals such as copper, silver, aluminum, and nickel. It can be widely used for welding controllable silicon leads, fuse strips, electrical leads, lithium battery poles, and pole ears.

Equipment features:

Equipped with high-performance ultrasonic metal spot welding power supply, automatically tracking the frequency of the transducer, with two control modes of time and energy;

★ Ultrasonic welding has low requirements for the metal surface and does not require scraping off the oxide layer or electroplating layer, resulting in high welding efficiency and quality;

★ Welding materials do not need to be melted, do not change material properties, and are pollution-free;

★ Can achieve welding between different metal materials, such as nickel+copper, copper+aluminum, nickel+aluminum, etc;

★ After welding, the metal material is conductive, with good thermal conductivity and low electrical resistivity, making it suitable for welding conductive materials

★ Short welding time, no need for any flux, protective gas, or filler. Using products:

★ Mutual melting of large heat sinks, heat exchange fins, and honeycomb cores for various household appliances and automotive products:

★ High current contacts such as electromagnetic switches and fuse less switches, as well as mutual fusion of dissimilar metal sheets;

★ Sealing, cutting, waterproofing, and airtightness of metal pipes.

Application field:

The ultrasonic wire harness welding machine is mainly used for welding copper and aluminum wires such as automotive wire harnesses and motorcycle wire harnesses.

Welding materials: copper wire, multi stranded wire, wire to wire fusion, wire to wire welding, bundle compression square equipment.

Welding method: Customize two welding surfaces for the welding head.