Automotive copper aluminum wire ultrasonic wire harness welding machine/high-power copper aluminum terminal ultrasonic wire harness welding machine

Place of Origin:Dongguan Guangdong

Brand Name:LINJIE

Certification:CE, ISO9001

Minimum Order Quantity:1 set

Packaging Details:Standard import and export wooden crates

Delivery Time:15 days

Payment Terms:50% T/T, 70% L/C

Applicable Industries: Automotive industry, home appliance industry etc.

Welding material:Metal, aluminum, copper, nickel etc.

Product Description:

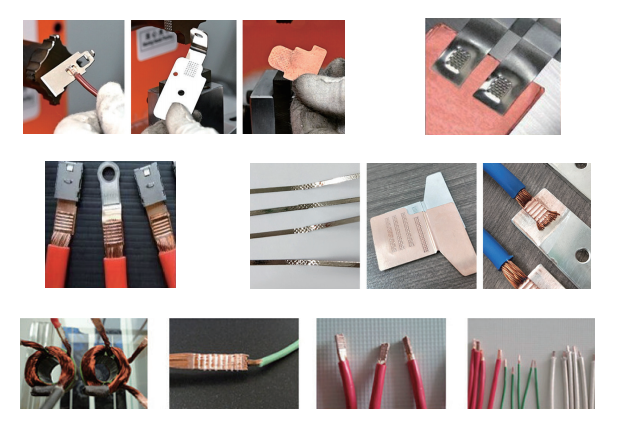

Linjie ultrasonic metal welding machine is a mechanical processing process that converts high-frequency electrical energy into mechanical vibration acting on the workpiece through a transducer device, causing high-frequency friction on the surface of the workpiece in contact with each other to generate heat and condense, resulting in fusion. During the welding process, there is no current passing through the workpiece, nor is there any welding arc generated in the welding mode. As ultrasonic welding does not have problems such as heat conduction and electrical resistance, it is suitable for non-ferrous metal materials, Undoubtedly, it is an ideal metal welding system, especially for fine and thin materials such as aluminum, nickel, copper, silver, etc., which can achieve ideal results through single point, multi-point, square, strip, single layer, multi-layer, and composite welding.

Product features:

1. Automatic frequency tracking technology (truly fully automatic frequency tracking, without frequency modulation during welding head replacement and welding process);The ultrasonic wire harness welding machine is mainly used for welding copper and aluminum wires such as automotive wire harnesses and motorcycle wire harnesses.

Welding materials: copper wire, multi stranded wire, wire to wire fusion, wire to wire welding, bundle compression square equipment.

Welding method: Customize two welding surfaces for the welding head.