Horizontal ultrasonic rotary plate welding machine/filter plastic welding machine/kettle ultrasonic plastic welding machine

Place of Origin:Dongguan Guangdong

Brand Name:LINJIE

Certification:CE, ISO9001

Minimum Order Quantity:1 set

Packaging Details:Standard import and export wooden crates

Delivery Time:15 days

Payment Terms:50% T/T, 70% L/C

Applicable Industries: Hotels, GarmentShops, Building Material Shops etc.

Welding material:ABS PP PC PE etc.

5. Partial clamping time coincides with welding time, resulting in higher productivity.

APPLICATION:

Plastic welding machines are widely used in the automotive industry, electronics industry, medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc.

Applicable products:

Automotive industry: plastic body parts, car doors, car instruments, car lights and mirrors, sunshades, interior parts, filters, reflective materials, reflective road studs, bumpers, cables, plastic filters for motorcycles, radiators, brake fluid tanks, oil cups, water tanks, fuel tanks, air ducts, exhaust purifiers, tray filters;

Plastic electronics: prepaid water and electricity meters, communication devices, cordless phones, mobile phone accessories, phone cases, battery cases, chargers, valve controlled sealed maintenance lead-acid batteries, 3-inch floppy disks, USB drives, SD cards, CF cards, USB connectors, Bluetooth;

Toys and stationery:folders, photo albums, folding boxes, PP hollow boards, pen cases, ink cartridges, toner cartridges;

Medical daily use: watches, kitchenware, oral liquid bottle caps, drip bottle caps, mobile phone accessories, gold brushes, daily necessities;

Hygiene products: children's products, air mattresses, hangers, knife handles, gardening products, kitchen utensils, showerheads, shower heads, anti-counterfeiting bottle caps, cosmetics bottle caps, coffee pots, washing machines, air dehumidifiers, electric irons, electric kettles, vacuum cleaners, speaker metal covers, and civil grilles.

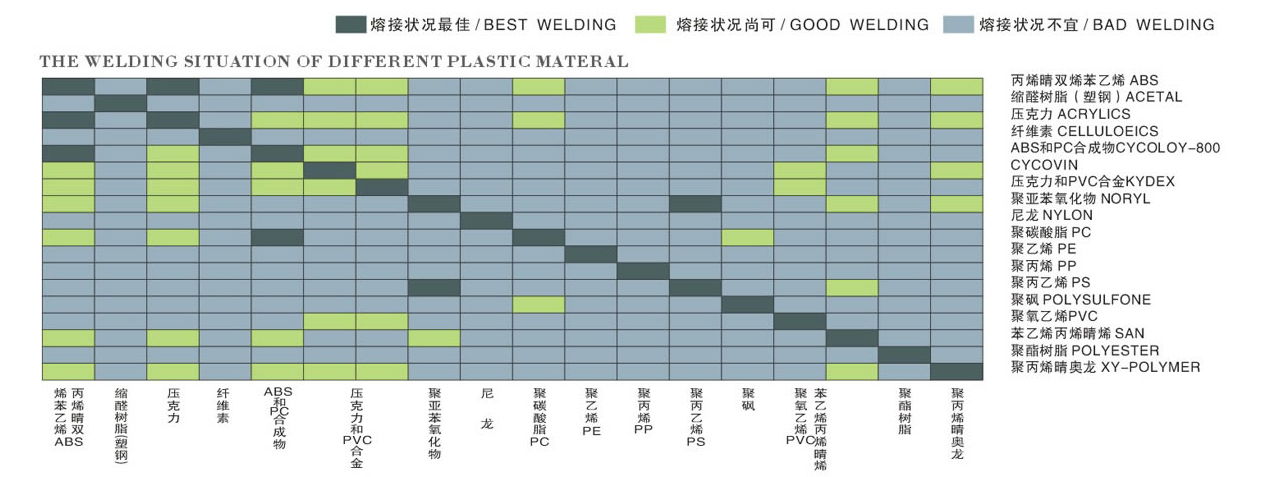

Different Material Matching Tables for Plastic Fusion Welding: