Introduction to LJ-V-8.3 Series Generators:

The LJ-V-8.3 intelligent series is another masterpiece meticulously crafted by Linjie Ultrasonic Company from 2018 to 2021. It uses a high-performance anti-interference microprocessor to achieve electronic control, and all parameters of fusion control are managed by a microcomputer. The intelligent frequency control system eliminates the inconvenience of manual frequency regulation, automatically detects sound overload, tracks the best resonance point in real time, and maintains the lowest temperature of the vibration group, The frequency changes with the increase of welding head temperature, and the machine automatically adjusts and operates more stably.

Principle of ultrasonic welding:

When ultrasonic waves act on the contact surface of thermoplastic materials, they generate tens of thousands of high-frequency vibrations per second. This high-frequency vibration, which reaches a certain amplitude, transmits ultrasonic energy to the welding area through the upper welded part. Due to the high sound resistance at the interface between the two welding areas, local high temperatures are generated. Unable to dissipate in time for a while, it gathered in the welding area, causing the contact surface of the two plastics to quickly melt. After adding a certain amount of pressure, it fused into one. After the ultrasound stops working, let the pressure continue for a few seconds to solidify and form a strong molecular chain, achieving the purpose of welding. The welding strength can be close to the strength of the raw material. The quality of ultrasonic plastic welding depends on three factors: the amplitude of the transducer's welding head, the applied pressure, and the welding time. The welding time and welding head pressure can be adjusted, and the amplitude is determined by the transducer and the amplitude lever. There is an appropriate value for the interaction between these three quantities. When the energy exceeds the appropriate value, the melting amount of plastic is large, and the welded material is prone to deformation; If the energy is small, it is not easy to weld firmly, and the applied pressure should not be too high. The optimal pressure is the product of the edge length of the welding part and the optimal pressure per 1mm of the edge.

Characteristics of LJ-V-8.3 generator:

1. High stability: Fully digital integrated circuit, using high-performance anti-interference processors imported from the United States, while reducing the number of components, simplifying hardware structure, and adding voltage stabilization function to improve system reliability and stability.

2. Frequency automatic tracking: The combination of digital frequency synthesis technology and digital phase-locked loop frequency tracking composite control technology can eliminate the shortcomings of temperature, static load, processing area, tool wear and other factors that are difficult to overcome by conventional analog regulators. It is conducive to parameter adjustment and facilitates the modification of program software, facilitating the adjustment of control schemes and the implementation of various new control strategies.

3. Strong output: The use of IGBT power modules combined with a separately excited oscillation circuit structure results in an output power that is more than 1.5 times that of traditional self-excited circuits.

4. Infinite amplitude adjustment: The amplitude can be instantly increased or decreased during the adjustment process, and can also be fine tuned, effectively preventing perfect welding of both large and small rubber parts, effectively reducing puncture and scalding, with defect monitoring function, more suitable for automated matching use, and the amplitude setting range is 10% to 100%

5. Intelligent protection and fault alarm prompt: mold current too high protection, frequency offset protection, total output too large protection. If the equipment malfunctions, the generator will immediately stop working and provide corresponding fault cause prompts until the technical personnel eliminate the fault.

6. The amplitude adjustment achieved by intelligent closed-loop amplitude control technology maintains a constant amplitude output due to the fluctuation of input power supply voltage and load.

7. Multiple welding mode switching enables higher welding accuracy, wider application range, and better fusion effect.

APPLICATION:

Plastic welding machines are widely used in the automotive industry, electronics industry, medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc.

Applicable products:

Automotive industry: plastic body parts, car doors, car instruments, car lights and mirrors, sunshades, interior parts, filters, reflective materials, reflective road studs, bumpers, cables, plastic filters for motorcycles, radiators, brake fluid tanks, oil cups, water tanks, fuel tanks, air ducts, exhaust purifiers, tray filters;

Plastic electronics: prepaid water and electricity meters, communication devices, cordless phones, mobile phone accessories, phone cases, battery cases, chargers, valve controlled sealed maintenance lead-acid batteries, 3-inch floppy disks, USB drives, SD cards, CF cards, USB connectors, Bluetooth;

Toys and stationery:folders, photo albums, folding boxes, PP hollow boards, pen cases, ink cartridges, toner cartridges;

Medical daily use: watches, kitchenware, oral liquid bottle caps, drip bottle caps, mobile phone accessories, gold brushes, daily necessities;

Hygiene products: children's products, air mattresses, hangers, knife handles, gardening products, kitchen utensils, showerheads, shower heads, anti-counterfeiting bottle caps, cosmetics bottle caps, coffee pots, washing machines, air dehumidifiers, electric irons, electric kettles, vacuum cleaners, speaker metal covers, and civil grilles.

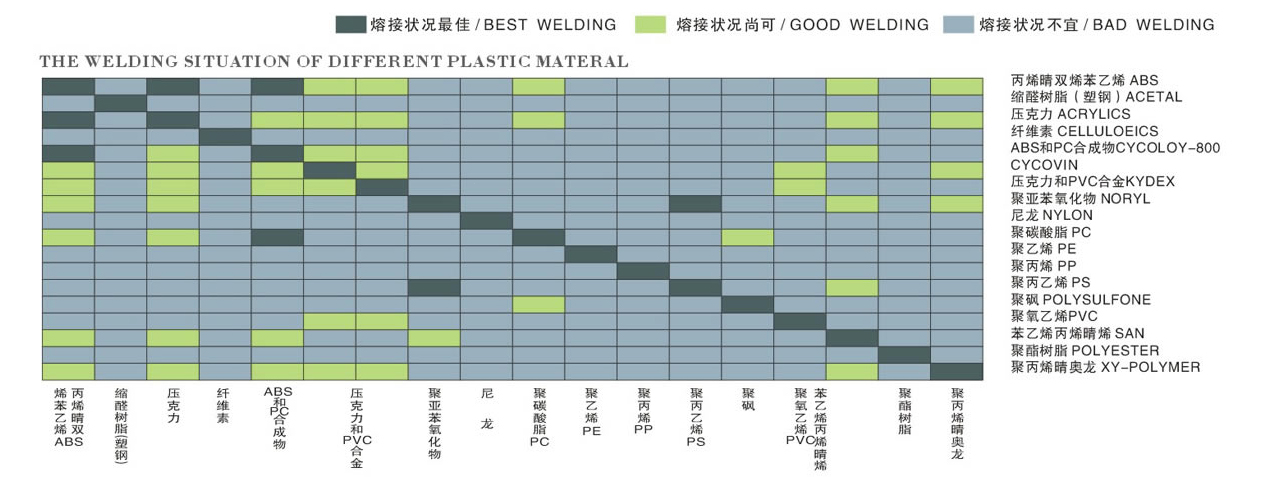

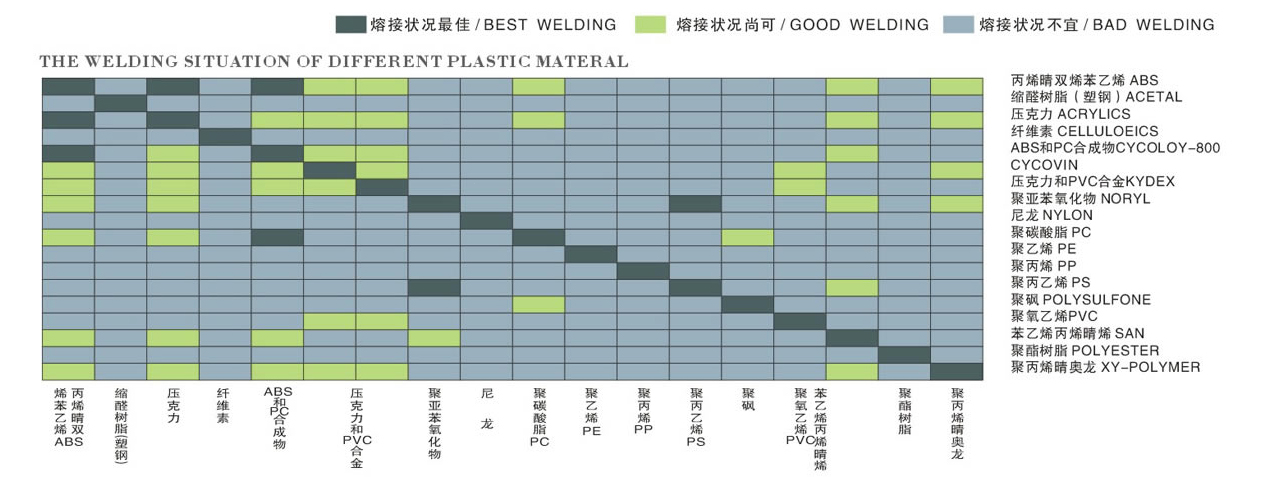

Different Material Matching Tables for Plastic Fusion Welding: