Equipment Description:

At present, the 15K or 20K ultrasonic waves widely used by various manufacturers in the market have serious problems such as easy breakdown and damage to internal chips when fusing high-precision electronic components. Since our company's research and development of a new high-precision 40K ultrasonic plastic welding machine was put into the market in the winter of 2008, it has received unanimous praise from various customers, and the use effect is very good, effectively solving the above difficult problems for customers.

Equipment features:

1. A complete set of high-quality imported parts combination, ensuring quality assurance. Adopting Taiwan Longyun cylinder and Jinqi solenoid valve;

2. Japanese original piezoelectric ceramic transducer, with uniform and stable output;

3. Imported steel variable amplitude pole, durable and long-lasting;

4. Automatic frequency search: First, design adjacent frequencies. The startup automatic test will run once, and the results of the actual working frequency of the ultrasound component will be stored and displayed with the current frequency;

5. Design frequency: First, confirm the approximate frequency of the transducer and the tool head, and then input the approximate frequency to set it (for example, estimate the combined frequency of the transducer to be about 20KHZ, and set the frequency between 20-20.5KHZ). The actual working frequency at the end of each welding is stored and displayed at the current frequency. After welding, due to the heating of the welding head or other factors causing frequency drift, it is always in the optimal resonance state and stored;

6. Shortening of Setting Time: Due to the expansion of the new control algorithm, mode tracking control, tracking memory control, amplitude gain control, and memory amplitude control have been achieved, which also shortens the positioning and setting time of cylindrical machinery

Function Description:

External power (energy) control adjustment: The power setting value of the controller can be freely adjusted. (Directly press the up and down button to adjust within the range of 1-100%) Internal limit setting: limits the maximum power output, suppresses the generation of excessive output, and prevents mechanical damage (external X has an actual control energy built-in) Power output slope: Users can set the power (amplitude) output rise time. Control the smooth start of operation through slope processing. (Soft start acceleration time)

Usage:

Suitable for small and high-precision tasks, such as soldering USB drives, SD cards, pacifiers, electronic chargers, and headphone plugs.

Applicable products:

Automotive industry: plastic body parts, car doors, car instruments, car lights and mirrors, sunshades, interior parts, filters, reflective materials, reflective road studs, bumpers, cables, plastic filters for motorcycles, radiators, brake fluid tanks, oil cups, water tanks, fuel tanks, air ducts, exhaust purifiers, tray filters;

Plastic electronics: prepaid water and electricity meters, communication devices, cordless phones, mobile phone accessories, phone cases, battery cases, chargers, valve controlled sealed maintenance lead-acid batteries, 3-inch floppy disks, USB drives, SD cards, CF cards, USB connectors, Bluetooth;

Toys and stationery:folders, photo albums, folding boxes, PP hollow boards, pen cases, ink cartridges, toner cartridges;

Medical daily use: watches, kitchenware, oral liquid bottle caps, drip bottle caps, mobile phone accessories, gold brushes, daily necessities;

Hygiene products: children's products, air mattresses, hangers, knife handles, gardening products, kitchen utensils, showerheads, shower heads, anti-counterfeiting bottle caps, cosmetics bottle caps, coffee pots, washing machines, air dehumidifiers, electric irons, electric kettles, vacuum cleaners, speaker metal covers, and civil grilles.

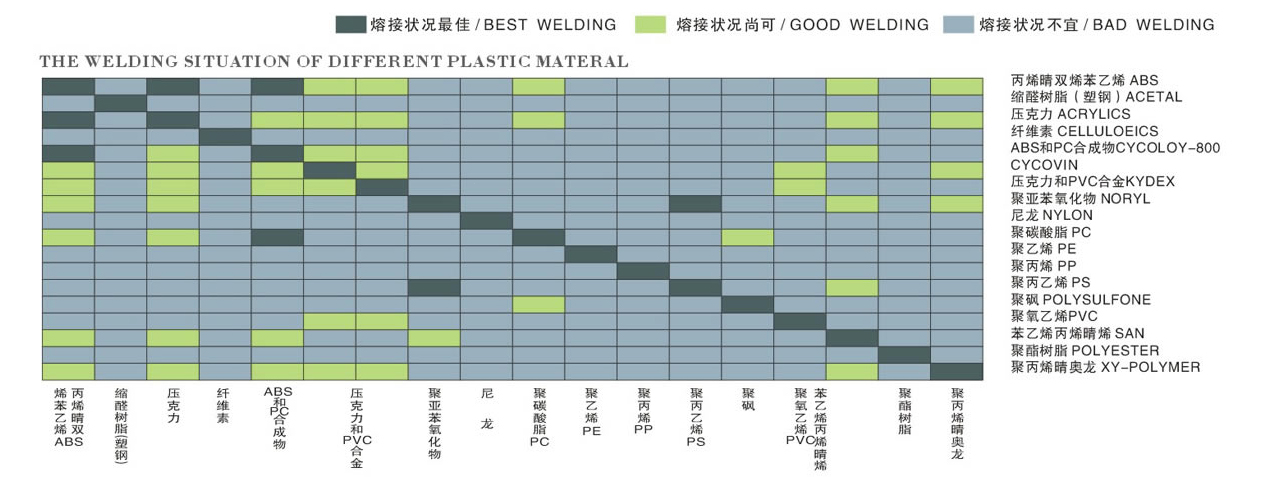

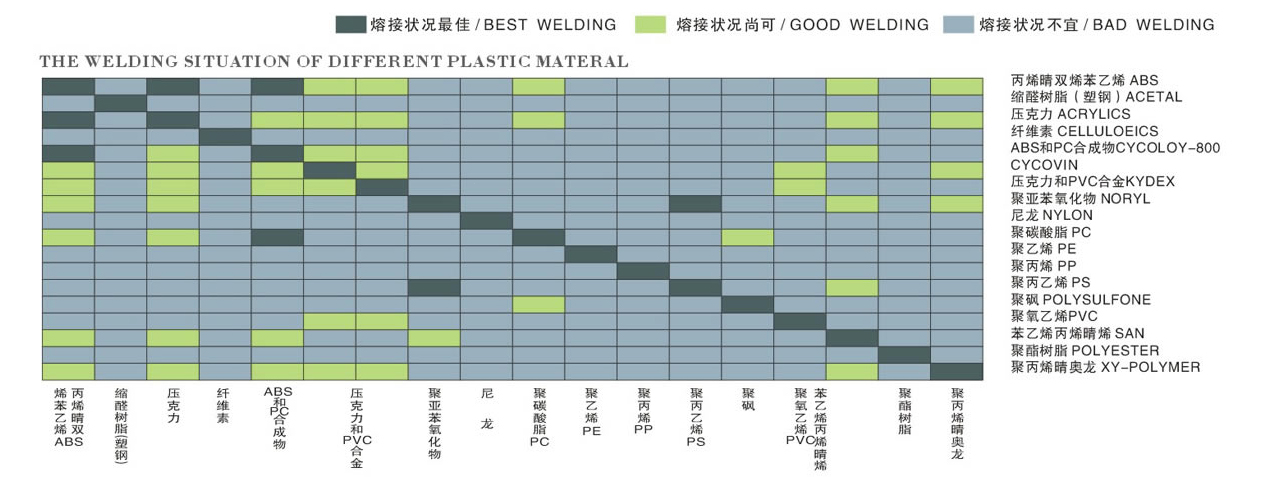

Different Material Matching Tables for Plastic Fusion Welding: