Exhaust light ultrasonic welding machine/plastic ceiling light welding equipment

Place of Origin:Dongguan Guangdong

Brand Name:LINJIE

Certification:CE, ISO9001

Minimum Order Quantity:1 set

Packaging Details:Standard import and export wooden crates

Delivery Time:15 days

Payment Terms:50% T/T, 70% L/C

Applicable Industries: Hotels, GarmentShops, Building Material Shops etc.

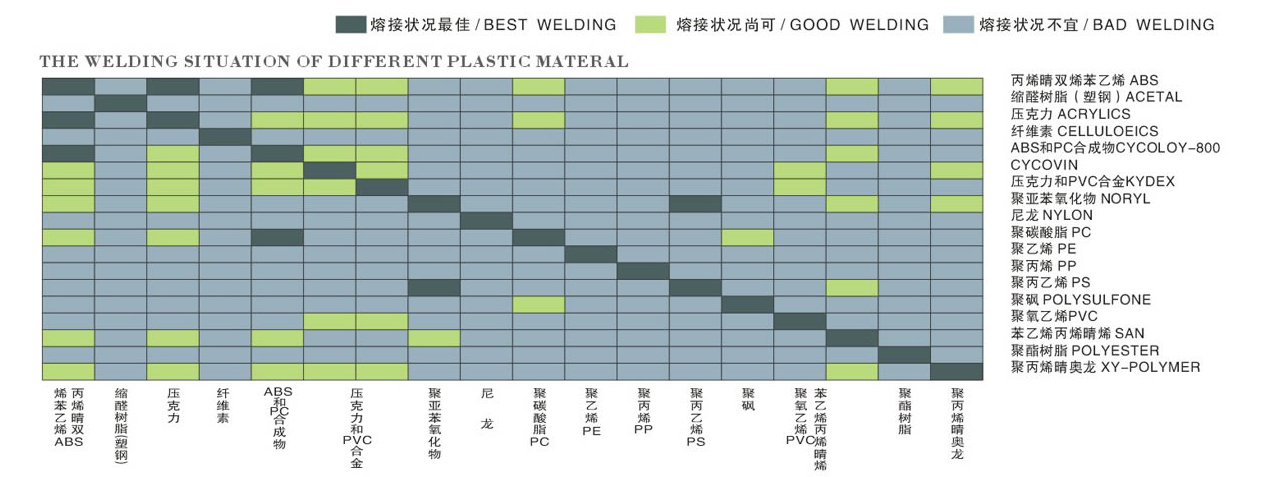

Welding material:ABS PP PC PE etc.

It can be automatically controlled. The ultrasonic output frequency is based on the frequency of the welding head and the frequency shift after the welding head temperature rises for a long time. Tracking to ensure that the equipment works at the best frequency point, so that the welded products are more stable, reliable and unified.

Product details:

The machine frame adopts a heavy-duty machine tool locking device, the overall structure is firm, stable, not easy to crack, and the reclining degree is 1/6 of other opening locking devices. Original NTK series transducer, imported cylinder, strong power and good stability.

Constant amplitude, digital display of various parameters, more intuitive debugging work status, humanized design, convenient for users to use.

PLC adopts Chinese and English dual language mode, self-developed computer control system, strong anti-interference ability, the speed can reach 0.001 second, and the adjustment is simple.

Advantages:

1. It eliminates the inconvenience of manual frequency adjustment, and automatically detects the frequency when it is turned on, making it more convenient and simple to use;

2. Built-in computer digitization of various parameters, automatic compensation amplitude, the amplitude is not large when the load is heavy, and the amplitude and power are amplified synchronously when the load is heavy, so as to effectively protect the transducer and the welding head mold, and the welding accuracy is higher;

3. The power output adopts digital stepless linear adjustment, and the output power can be freely selected from 50% to 100%. The internal power amplification adopts a full-bridge IGBT module, with high ultrasonic conversion rate, and the maximum ultrasonic power can reach 7200W, which can meet various welding requirements;

4. More advanced protection circuit, the output sound wave is overloaded, the mold is suddenly broken and overloaded, and the built-in computer detection circuit cuts off the output in a very short time to protect the internal circuit;

5. High-speed switching work up to 235 times per minute, which can be adapted to welding of various non-standard automation equipment;

6. The operation interface can choose Chinese or English, which is more convenient for foreign purchasers.

Features:

※The overall appearance is streamlined, and the surface is sprayed with corrosion resistance;

※Base level adjustable design, convenient and accurate adjustment;

※Circular thickened column, linear guide bearing, precision fine-tuning device;

※It adopts imported touch screen full Chinese liquid crystal display computer control system, which is safer and more accurate;

※Original NTK transducer, high power, high conversion efficiency, suitable for welding large plastic parts;

※Frequency offset, overload and other protective measures to avoid improper operation LED display various parameters;

APPLICATION:

Plastic welding machines are widely used in the automotive industry, electronics industry, medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc.

Automotive industry: plastic body parts, car doors, car instruments, car lights and mirrors, sunshades, interior parts, filters, reflective materials, reflective road studs, bumpers, cables, plastic filters for motorcycles, radiators, brake fluid tanks, oil cups, water tanks, fuel tanks, air ducts, exhaust purifiers, tray filters;

Plastic electronics: prepaid water and electricity meters, communication devices, cordless phones, mobile phone accessories, phone cases, battery cases, chargers, valve controlled sealed maintenance lead-acid batteries, 3-inch floppy disks, USB drives, SD cards, CF cards, USB connectors, Bluetooth;

Toys and stationery:folders, photo albums, folding boxes, PP hollow boards, pen cases, ink cartridges, toner cartridges;

Medical daily use: watches, kitchenware, oral liquid bottle caps, drip bottle caps, mobile phone accessories, gold brushes, daily necessities;

Hygiene products: children's products, air mattresses, hangers, knife handles, gardening products, kitchen utensils, showerheads, shower heads, anti-counterfeiting bottle caps, cosmetics bottle caps, coffee pots, washing machines, air dehumidifiers, electric irons, electric kettles, vacuum cleaners, speaker metal covers, and civil grilles.

Different Material Matching Tables for Plastic Fusion Welding: