Magnifier frame ultrasonic welding machine/vacuum cleaner plastic shell ultrasonic welding machine

Place of Origin:Dongguan Guangdong

Brand Name:LINJIE

Certification:CE, ISO9001

Minimum Order Quantity:1 set

Packaging Details:Standard import and export wooden crates

Delivery Time:15 days

Payment Terms:50% T/T, 70% L/C

Applicable Industries: Hotels, GarmentShops, Building Material Shops etc.

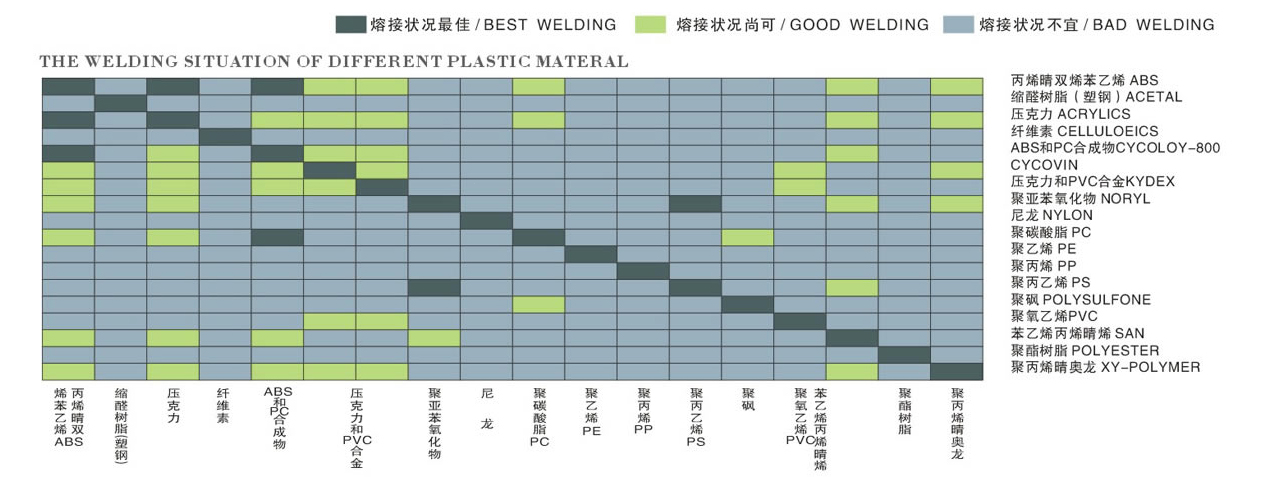

Welding material:ABS PP PC PE etc.

High-performance anti-jamming microprocessor is used to realize electronic control. All parameters of welding operation are managed by microcomputer. Intelligent frequency control system eliminates the inconvenience of manual frequency adjustment. Automatic detection of sound wave overload, real-time tracking of the best resonance point, vibration The temperature of the group is kept at the lowest point, the frequency of the welding head temperature rises and the frequency changes, and the machine automatically adjusts and runs more stably.

Precision ultrasonic welding machine:

1. It adopts Japan (IK0) precision cross guide rail, Germany (FESTO) running components and control system.

2. Imported transducer, strong energy, titanium alloy amplitude modulator, durable.

3. The square column and steel frame are stable and firm without backlash under high pressure and fast operation.

4. High stability, all-digital integrated circuit, high-performance anti-jamming processor imported from the United States, while reducing the number of components and simplifying the hardware structure, thereby improving the reliability of the system.

5. Frequency automatic tracking, digital frequency synthesis technology combined with digital phase-locked loop frequency tracking compound control technology, can eliminate the shortcomings of temperature, static load, processing area, tool wear and other factors that are difficult to overcome by conventional analog regulators, which is beneficial to parameters It is convenient to adjust the control scheme and realize a variety of new control strategies through the modification of the program software.

6. Strong output, the application of IGBT power module and the structure of his excitation oscillation circuit make the output power more than 1.5 times that of the traditional self-excitation circuit.

7. It can be set to store 100 sets of different welding parameters for molds. The best parameters for each set of mold welding are found on the equipment and stored as a group. When the machine is adjusted next time, the corresponding group of stored parameters can be selected to quickly and automatically adjust to the best parameters.

8. Intelligent three protections and fault alarm prompts: mold current over-high protection, frequency offset protection, and total output over-large protection. When the equipment breaks down, the generator will stop working immediately, and give a corresponding prompt of the cause of the failure, until the technician checks the failure.

9. Intelligent closed-loop amplitude control technology realizes amplitude adjustment without being affected by input voltage and load fluctuations. maintain a constant amplitude output.

10. Built-in magnetic scale distance measuring device and pressure sensing device.

11. Six welding modes and three trigger modes can be flexibly switched at will, and the best welding mode can be selected according to product characteristics, which makes up for the shortcomings of traditional welding modes and makes welding more precise and more effective.

12. The amplitude can be adjusted steplessly. The amplitude can be increased or decreased instantly during the adjustment process, and can also be fine-tuned. Both large and small plastic parts can be perfectly welded, effectively reducing defective products such as breakdown and burns. The setting range of the amplitude is 10%~100%

13. Recipe call, you can store the best parameter group for each mold welding production to the corresponding number, you can directly select the number with the parameters stored in the next use, and the parameters of each part can be restored to the parameters when it was stored .

14. Welding record query, support download function.

Features:

Precise: the control accuracy can reach 0.02mm

Stability: square column, steel frame, no back tilt

Efficient: no screws, no glue, less labor, low cost

Reliable: no water leakage, no air leakage, airtight welding, no damage to plastic parts during welding

APPLICATION:

Plastic welding machines are widely used in the automotive industry, electronics industry, medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc.

Applicable products:

Automotive industry: plastic body parts, car doors, car instruments, car lights and mirrors, sunshades, interior parts, filters, reflective materials, reflective road studs, bumpers, cables, plastic filters for motorcycles, radiators, brake fluid tanks, oil cups, water tanks, fuel tanks, air ducts, exhaust purifiers, tray filters;

Plastic electronics: prepaid water and electricity meters, communication devices, cordless phones, mobile phone accessories, phone cases, battery cases, chargers, valve controlled sealed maintenance lead-acid batteries, 3-inch floppy disks, USB drives, SD cards, CF cards, USB connectors, Bluetooth;

Toys and stationery:folders, photo albums, folding boxes, PP hollow boards, pen cases, ink cartridges, toner cartridges;

Medical daily use: watches, kitchenware, oral liquid bottle caps, drip bottle caps, mobile phone accessories, gold brushes, daily necessities;

Hygiene products: children's products, air mattresses, hangers, knife handles, gardening products, kitchen utensils, showerheads, shower heads, anti-counterfeiting bottle caps, cosmetics bottle caps, coffee pots, washing machines, air dehumidifiers, electric irons, electric kettles, vacuum cleaners, speaker metal covers, and civil grilles.

Different Material Matching Tables for Plastic Fusion Welding: