Plastic tray welding machine/filter plastic docking machine/plastic cosmetic bottle cap welding machine

Place of Origin:Dongguan Guangdong

Brand Name:LINJIE

Certification:CE, ISO9001

Minimum Order Quantity:1 set

Packaging Details:Standard import and export wooden crates

Delivery Time:15 days

Payment Terms:50% T/T, 70% L/C

Applicable Industries: Hotels, GarmentShops, Building Material Shops etc.

Welding material:ABS PP PC PE etc.

Ultrasonic plastic welding machine product introduction:

The ultrasonic waves are transmitted to the plastic processing parts through the welding head, so that the two plastic joint surfaces are subjected to intense friction due to the action of ultrasonic waves, and the frictional heat melts the plastic joint surfaces to complete the gluing. This technology has the advantages of high speed, strong weld seam, etc., and more importantly, it can automate the production and processing of plastic products. Ultrasonic plastic welding machine can be used for plastic welding, embedding, forming, riveting, spot welding, cutting, sewing and other operations. As long as the welding head is changed, one machine can be used for multiple applications.

Machine Features:

Precision cast aluminum alloy base, seamless steel tube column, good rigidity, no bending when pressed down.

The first electric lift, easy and convenient to adjust.

The NTK vibrator made in Japan is matched with ace steel and titanium alloy transducers, which are strong and durable.

Electronic frequency tracking, overall mother-child circuit board design.

The downward position of the mold is equipped with a precision scale mechanical fine-tuning device.

Working Features:

Fast - each welding time is 0.01-9.99 seconds.

Strength - can withstand large tension and high pressure.

Quality - no water leakage, no air leakage, can be welded airtight, no damage to plastic parts during welding.

Economical - no screws or glue required. Reduce labor and lower costs.

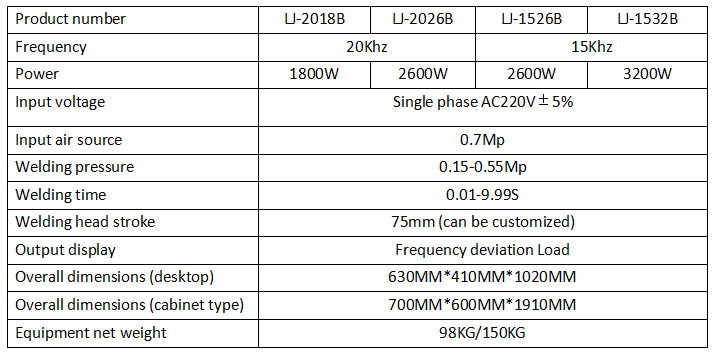

Product parameters:

Application: